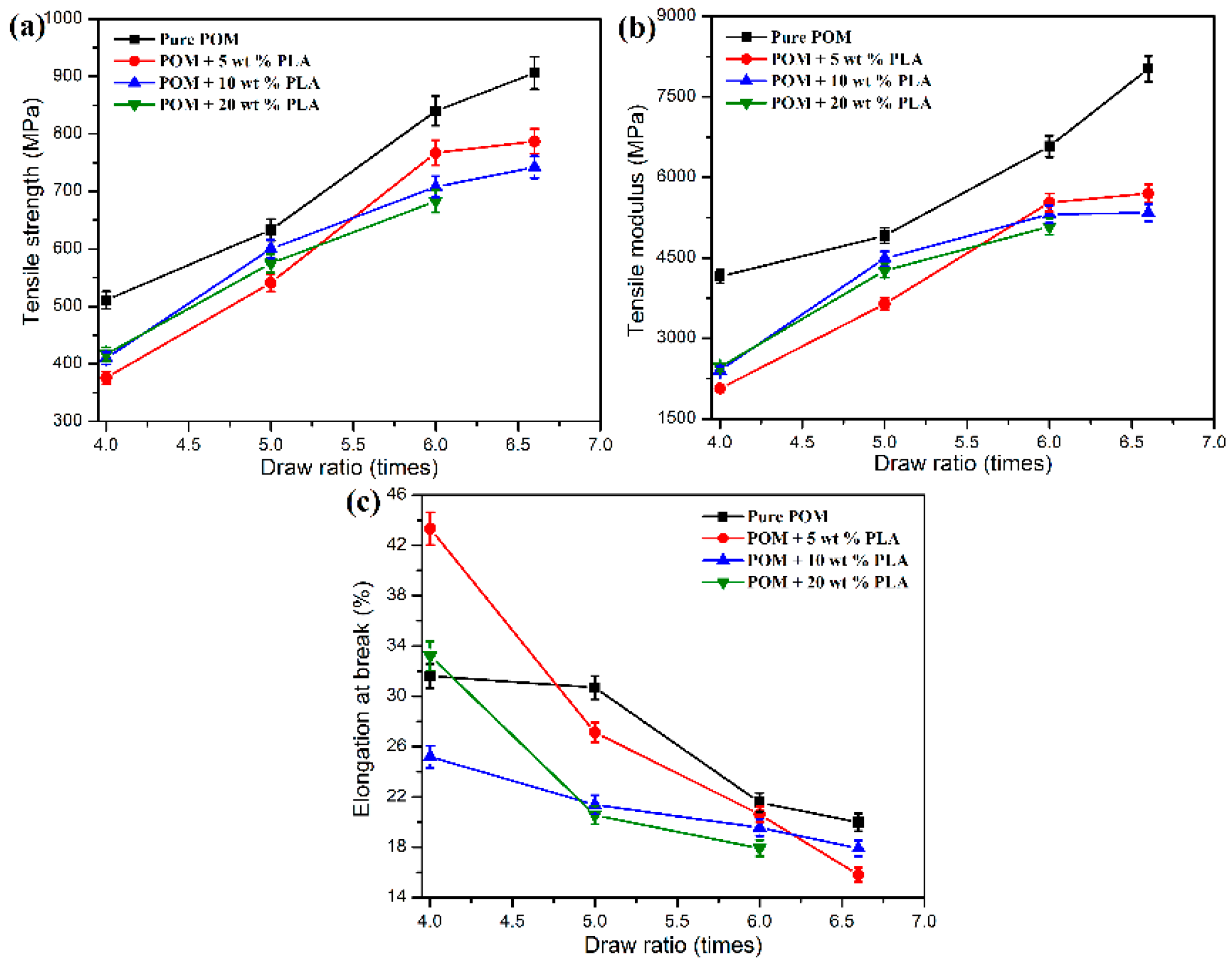

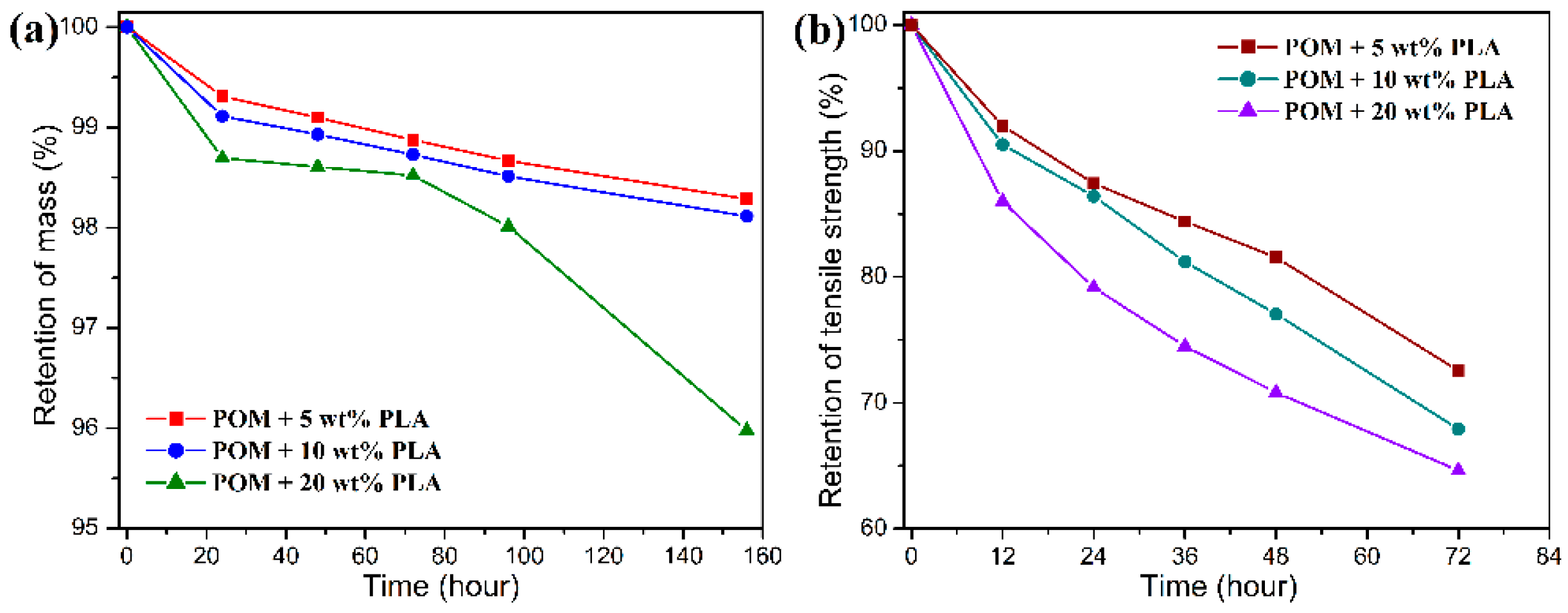

Polymers | Free Full-Text | Crystalline Characteristics, Mechanical Properties, Thermal Degradation Kinetics and Hydration Behavior of Biodegradable Fibers Melt-Spun from Polyoxymethylene/Poly(l-lactic acid) Blends | HTML

Polymers | Free Full-Text | Crystalline Characteristics, Mechanical Properties, Thermal Degradation Kinetics and Hydration Behavior of Biodegradable Fibers Melt-Spun from Polyoxymethylene/Poly(l-lactic acid) Blends | HTML

Delrin CPE – A New Platform of Emission-minimized POM Homopolymers with Optimized Processing Efficiency I PlasticPortal.eu

Polymers | Free Full-Text | Crystalline Characteristics, Mechanical Properties, Thermal Degradation Kinetics and Hydration Behavior of Biodegradable Fibers Melt-Spun from Polyoxymethylene/Poly(l-lactic acid) Blends | HTML

Is there any ductile material where there is no difference between ultimate strength and breaking strength? - Quora

Determined temperature trends of contact comparison stress and yield... | Download Scientific Diagram

9. Tensile strength in dependence on test temperature for different... | Download Scientific Diagram

Tensile properties of polyformaldehyde blends and nanocomposites in: Journal of Polymer Engineering Volume 35 Issue 5 (2015)

3 . Mechanical Properties 3・ 1 Tensile Strength The stress-strain curve when tension is applied to ASTM-D638 type 1 test p

![Material properties of POM and PA66 [7] | Download Scientific Diagram Material properties of POM and PA66 [7] | Download Scientific Diagram](https://www.researchgate.net/publication/335165430/figure/tbl1/AS:791790051393538@1565788867902/Material-properties-of-POM-and-PA66-7.png)

.jpg)

.jpg)